A Smarter Way to Measure and Monitor Level

The methods and technologies used to measure and monitor level applications continue to evolve over time. The demands of accurate, reliable and precise level measurements are becoming more critical for everything from EPA reporting in municipalities to maximizing business profitability. There is now a smarter and more efficient way to measure and monitor level applications by implementing predictive and preventative maintenance. Industry 4.0 enabled level sensors is the latest industrial revolution to hit the process instrumentation market. Using smart technology, the internet of things (IoT) sensors are equipped with improved communications, predictive analysis and remote diagnostics to provide the most efficient and effective level measurement methods.

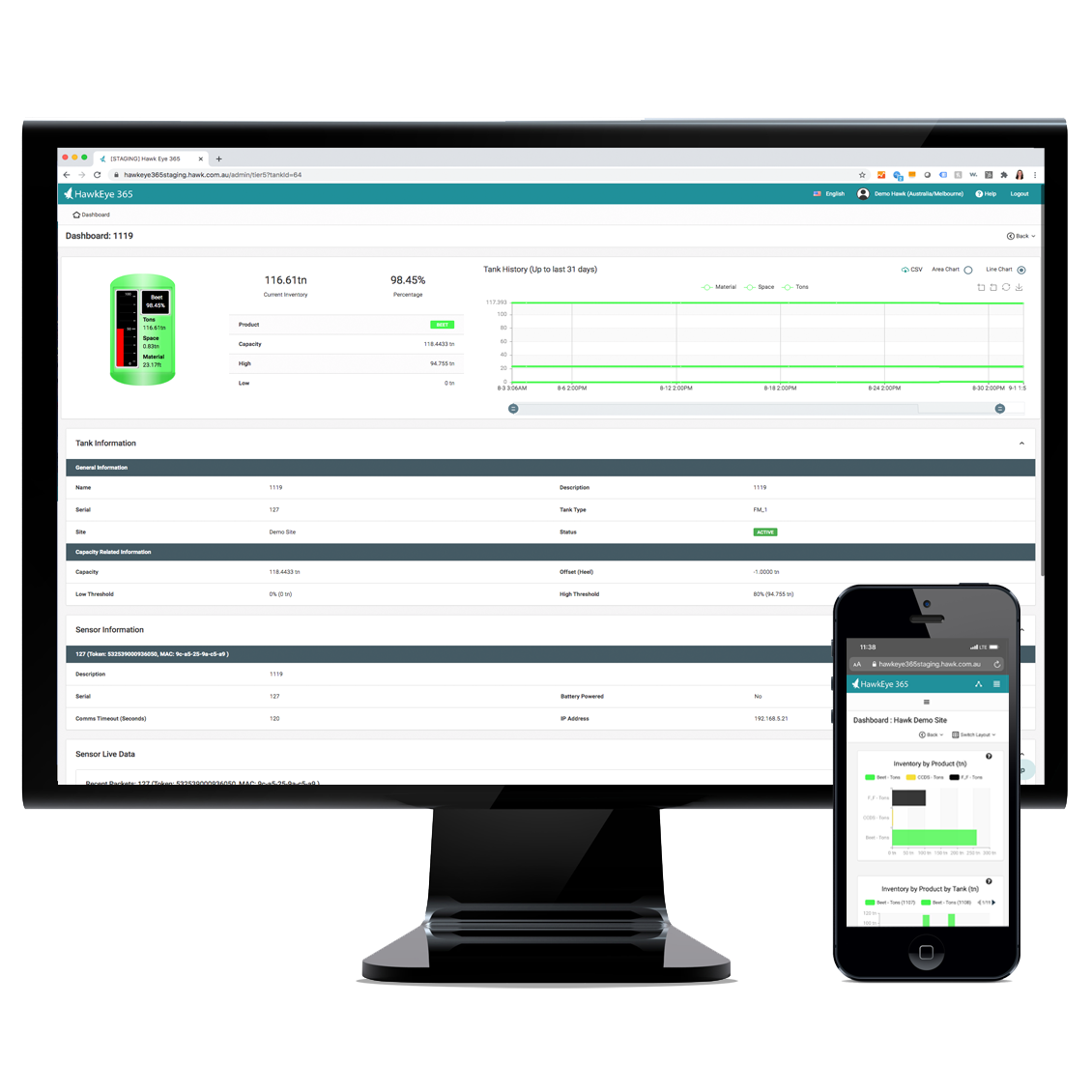

Hawk Measurement (HAWK) is a company known for solving difficult level measurement applications within the harshest of environments. Their recent line of industry 4.0 sensors includes the world’s first Power over Ethernet (PoE) level transmitters. The advantages to PoE connectivity are secure in-plant and remote level monitoring as well as predictive maintenance, remote sensor setup, diagnostics and troubleshooting capabilities. The PoE enabled level sensors can be maintained and monitored from anywhere in the world via the HawkEye365 cloud-based web portal. The HawkEye365 portal provides the ability to view and monitor tank health, retrieve data and receive alarms from a smart phone, tablet or computer. The HawkEye365 portal is not only compatible with PoE transmitters but is also sensor agnostic and can monitor any type of field device (not just HAWK brand) such as level, flow, pressure, temperature and pH.

HAWK currently provides two types of level technologies that are equipped with PoE capabilities. The Sultan Acoustic Wave Level Transmitter with PoE is ideal for level, flow, positioning and collision protection to a distance of 60m (196ft) or up to 180m (588ft) for extended ranges. HAWK is the only company on the market to offer PoE connectivity for Acoustic Wave Level Measurement. This rugged, self-cleaning sensor requires zero maintenance and is ideal for measuring level of liquids, slurries, and solids. The combination of low frequency, high power, and signal processing (Adaptive Gain Technology) creates one of the world's most reliable level devices available on the market.

The second PoE enabled level sensor is the Centurion Guided Radar (CGR) Level Transmitter. The CGR features Guided Wave Radar technology and is ideal for level measurement of liquids, solids, bulk materials, sludge, powders, granules for Level and Interface to a distance of 38m (124ft). This technology is not affected by pressure, temperature, viscosity, vacuum, foam, dust, changes in dielectric constant or coating of the probe. Multiple CGR units can be connected to a powered switch and data can be streamed over any standard network, for local and remote control, management and monitoring.

There are many benefits to industry 4.0 and PoE enabled devices. By implementing smart communications and practices, it provides predictive and preventative methods that allow the client to optimize their process to the fullest capabilities. Avoid tank overflows, provide continuous and reliable level measurement and stay connected 24/7 with inventory assets. This type of real-time intelligent measurement and monitoring is critical to operating efficiently and protecting valuable assets.

Industry 4.0 Compatible Products

The HawkEye365 Online Inventory Asset and Monitoring Portal is a complete remote and in-plant measurement and monitoring system. Unlike anything on the market today, this system is uniquely different due to the communications capabilities and compatibility with HAWK's Power over Ethernet level sensors. The advantages to Power over Ethernet connectivity are secure in-plant and remote monitoring, as well as remote sensor setup, diagnostics and troubleshooting abilities. The HawkEye365 portal is not only compatible with PoE transmitters, but is also sensor agnostic and can monitor any type of field device such as level, flow, pressure, temperature and pH. The multiple communication methods include RS485, HART, Modbus, Ethernet TCP/IP, Cellular, Bluetooth and PoE.

The Sultan Acoustic Wave Level Transmitter with Power over Ethernet (PoE) is ideal for level, flow, positioning and collision protection to a distance of 60m (196ft) or up to 180m (588ft) for extended ranges. HAWK is the only company on the market to offer PoE connectivity for Acoustic Wave Level Measurement. This rugged, self-cleaning sensor requires zero maintenance and is ideal for measuring level of liquids, slurries, and solids. The combination of low frequency, high power, and signal processing (Adaptive Gain Technology) creates one of the world's most reliable level devices available on the market.

The Award-Winning Centurion Guided Radar (CGR) Level Transmitter is ideal for the measurement of liquids, sludge, powders and granules to a range of 38m (124ft) for level and interface measurement. This technology is not affected by pressure, temperature, viscosity, vacuum, foam, dust, changes in dielectric constant or coating of the probe. HAWK’s CGR won the prestigious Chemical Processing 2021 Vaaleer Awards and Process Instrumentation's Product of the Year Award. HAWK's CGR is the first and only guided wave radar on the market to feature Power over Ethernet (PoE) communications. The advantages to PoE connectivity are secure in-plant and remote monitoring, as well as remote sensor setup, diagnostics and troubleshooting abilities.

HAWK's AccuTank Radar Level Monitoring System is the most precise, reliable and innovative remote monitoring system on the market. This affordable system comes with everything you need to receive e-mail alerts, configure and remotely monitor tank levels from practically anywhere in the world.

The Transmix-ID™ is a clamp-on sensor capable of detecting and identifying liquid interfaces in flowing pipelines. The Transmix-ID™ technology is so revolutionary, it can decipher the difference between 87 Octane Gas and JP-8 Fuel when both liquids are flowing through a pipe. The non-intrusive unit can fit to any size pipe or container and is independently powered. The Transmix-ID™ is equipped with WiFi, Cellular or Satellite communications (or any combination thereof). The cloud-based monitoring portal identifies the liquid flowing through the pipeline and reports issues in real-time to even the most remote areas.

The Alarm-ID™ is a tank overfill and underfill protection system. This PST patented technology provides an alarm point when the identified liquid passes the sensor level either up or down. A series of Alarm-ID™ Units can be installed at key levels on the outside of tanks. The tank contents and even vacancy can be detected and alerts are activated in real-time 24/7.

The Gladiator Gen 3 Microwave Switch can be used for blockage detection, barrier detection, machine detection, collision detection for protection, point level measurement, and detection of objects or material between two points.

The Gladiator Gen 1 Microwave Switch can be used for blockage detection, barrier detection, machine detection and point level measurement, and detection of objects or material between two points.

The Gladiator Acoustic Switch can be used for blockage detection, barrier detection, machine detection / protection and point level measurement, and detection of objects or material between two points.

The Praetorian Conveyor Health Monitoring System (CHMS) is a plant & site-wide single solution for detecting when critical parts of the idler are beginning to fail. The early detection warnings allow operators to control downtime and avoid catastrophic costly unplanned shutdowns. HAWK's Praetorian Fiber Optic Sensing detects abnormalities in conveyor idler performance that other technologies cannot.

The Praetorian Fiber Optic Sensing System can be installed along a fence or perimeter and can detect, identify and report any movements. This system has limitless applications and can be installed on anything from explosive storage areas to farms and ranches. The fast processing speed and pulse rate allow the Fiber Optic System to detect minute interferences that may otherwise go unnoticed. Some examples of detectable activates include intruder movement along a perimeter, intruders cutting or climbing a fence, vehicle movement along a perimeter and digging, excavating or trenching. The Fiber Optic Sensing system is crucial for keeping valuable assets secure and protected.

The Praetorian Fiber Optic Sensing System can be installed on a buried or unburied pipeline and can immediately detect pipeline leakage, ground disturbances, manual and machine excavation, theft, hot tapping and vehicle movement. The Fiber Optic System continually monitors large spans of pipeline, looking for vibration and temperature changes. Once a detection occurs, the system alerts the operator or security personal to the exact location of disturbance in the pipeline. This type of real-time intelligent monitoring is critical to operating efficiently and protecting valuable assets.

The Praetorian Fiber Optic Sensing System can monitor buried and unburied data cables, wires and power transmission lines. Monitoring for wear, damage or corrosion of the cable is extremely difficult and often power failure or data outage is the first sign of a problem. These cables are typically installed in areas that have multiple uses by various stake holders and in the event of a failure can be logistically difficult and expensive to access for repair. The Praetorian Fiber Optic Sensing System can be installed either near the power cables or embedded within the power cable itself. It can monitor disturbances, identify manual and machine excavation, vehicle movement, ground condition assessment and detects hotspots. HAWK’s Fiber Optic Sensing System requires no additional field infrastructure such as power or communication and does not require maintenance or calibration after commissioning.

Tailings Dams are massive structures used all over for the bulk storage of mineral processing wastes. These earthen structures can measure tens of kilometers in length and width and be hundreds of meters tall. In terms of total volume tailings dams are the largest manmade structures in existence. However, over the last 20 years the rate of tailings dams failing has doubled. Failures of tailings dams are perhaps the worst possible case scenario for any mineral extraction operation. Events causing loss of life in the hundreds or even thousands, Environmental fines reaching billions of dollars and the loss of facility infrastructure and production are a confronting prospect. HAWK has developed a solution to prevent tailings dams failure. HAWK's Praetorian Geological Stress Detection System utilizes fiber optic sensing technology for the real time monitoring of field strain within earthen structures. This revolutionary technology uses fiber optic cables that are then inserted into the structure through drilled boreholes. These cables monitor field strain and deflection caused by dam loading and report both the borehole position and depth where the strain or deflection is occurring within the retaining wall structure. Sensitivities achievable with the Praetorian Geological Stress Detection System means that potential issues with ground shift can be detected and intercepted well in advance of visually symptoms of structural issues.